Flexfiller Plus

Flexfiller Plus & Midifill Plus

Compact, totally enclosed combined digital pressurisation unit with vacuum degasser for use on sealed systems in order to provide

a minimum system pressure requirement and effective dissolved gas removal.

The Flexfiller Plus and Midifill Plus are compact, totally enclosed combined digital pressurisation units with vacuum degasser for

use on sealed systems in order to provide a minimum system pressure requirement and effective dissolved gas removal.

System Volume (Guide): < 300,000 litres (Midifill Plus 150D: < 50,000 litres)

Application of Use:

• Commercial.

• Industrial.

• Residential.

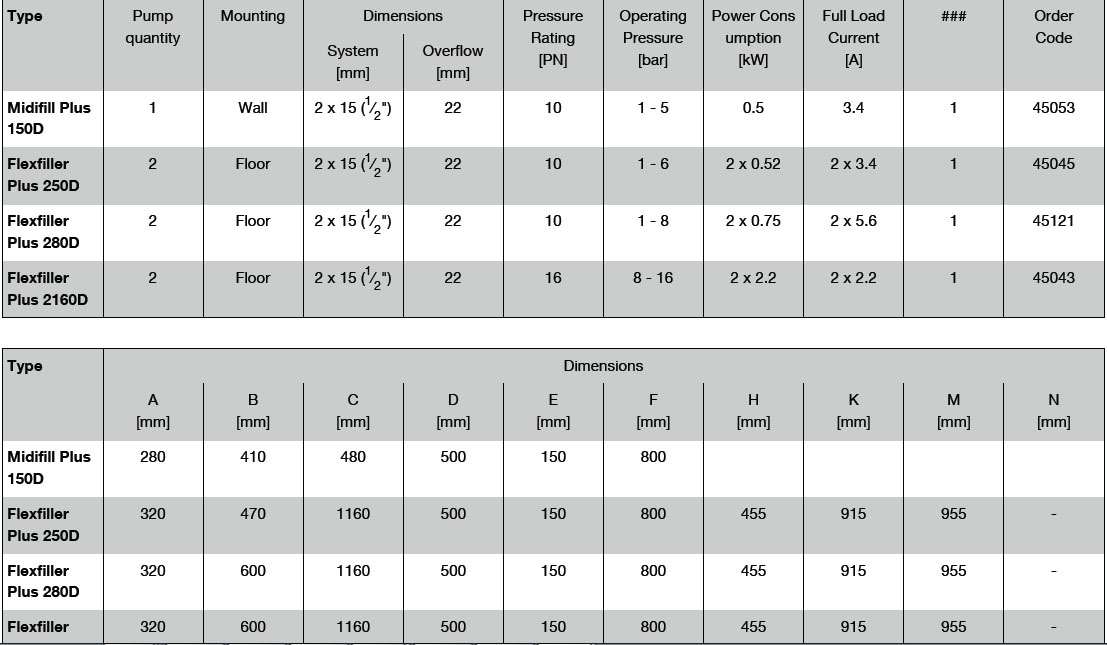

Type Pump

quantity

Advantages

Product Features:

• For system volumes up to 300,000 litres.

• Break Tank: 18 litre break tank with type AB Air Gap Fluid Cat 5 (Midifill Plus: 4 litre).

• System quick-fill mode.

• Password protection for parameter entry.

• Pressure settings in 0.1 bar increments.

• Service reminder option (12 months).

• Pump pulse option (2 second pulse if inactive for 60 days).

• Flood protection options.

• Event logging for pump start, individual pump run hours counter, electrical interruption and common alarm.

• Volt free contacts for common fault, high pressure, low pressure, pump fault, pressure transducer (Top-up controller only).

• Individual controllers for pressurisation and degassing function.

• Vacuum degassing, turbo and normal interval modes.

• Electric pump, 230V 50Hz 1ph (2160D: 415V 50Hz 3ph).

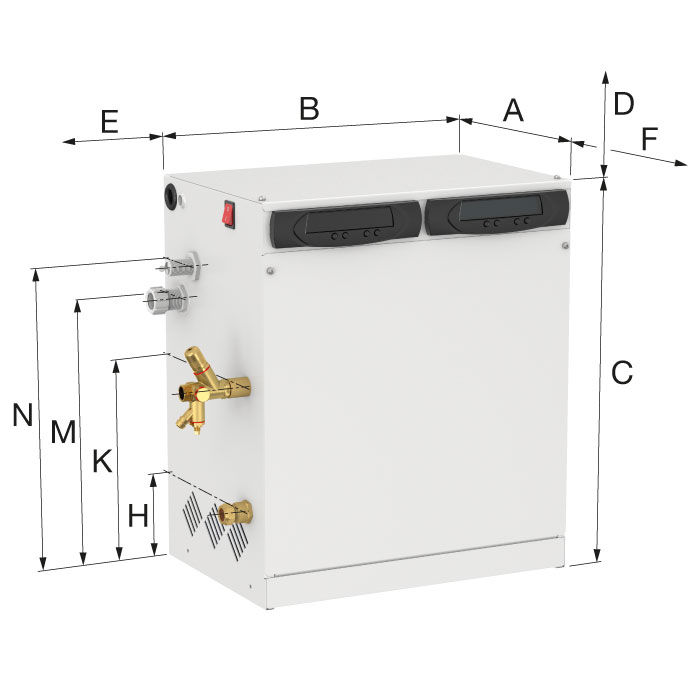

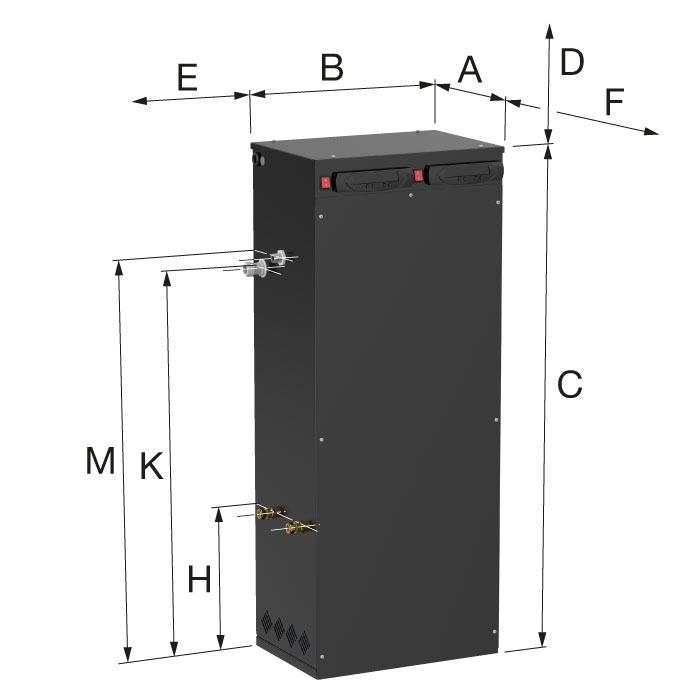

•Colour Flexfiller Plus: Black (RAL 9005).

• Colour Midifill Plus: White (RAL 9910).

Technical information

Certifications and Standards Applied:

• PED 2014/68/EU Sound Engineering Practice.

• IEE – Electrical Safety Guidance.

• EMC 2004/108/EC.

• BS7074 Parts 1 to 3.

• Machinery Directive 95/16/EC.

• Electronic Components have been tested and comply with the EMC Directives.

• EN61000-6-2: Generic Standards – Immunity standard for industrial environments.

• EN61000-6-3: Generic Standards – Emission standard for residential, commercial and light industrial environment.

• CE marked components, where applicable.

• WRAS approved float valve to BS1212 part 2.

• IP54 (BS EN60529) Rated Controller.

Material of Construction:

• Cabinet: Mild steel CR4.

• Float: WRAS Approved Beta Side Entry.

• Break Tank: WRAS Approved Polypropylene.

• Cylinder: Stainless steel 304.

• Pump: PEDROLLO (Unit dependant. See pump details for more information).

• Valves: Brass.

• Connection: Brass / Polypropylene.

• Pipework: Braided flexihose / EPDM / Copper.

• Finish: Powder Coating.

Operating Conditions:

• System Temperature Range: 0 – 90 °C.

• Ambient Temperature Range: 0 – 45 °C.

• Maximum system temperature at the Point of connection: 70 °C.

• Safety Rating: IP 54.

• Maximum Turbo Runtime: 168 hours (1 week).

• Maximum Normal Downtime: 180 minutes (3 hours).

• Relative humidity 95% non-condensing.

• Noise Rating Data: < 75 dBA.