Grooved Pipe Joining System

Since 1925, Victaulic has been at the forefront of mechanical piping systems innovation, providing numerous patented piping related products that are in use today in multiple markets around the world. And they all stem from one basic concept; the original grooved end mechanical pipe joining system and a steady stem of innovation from Victaulic. The Victaulic grooved end piping system is the most versatile, economical and reliable mechanical pipe joining system available. Grooved pipe joining solutions provides an unmatched competitive edge by reducing installation time, making installations safer and providing design versatility unmatched in mechanical piping systems technology.

By installing Victaulic, conserve time and financial resources through:

- Compressed project schedules

- Lowered total installed cost

- Safer work environment

Install up to 10 times faster than other pipe joining methods.

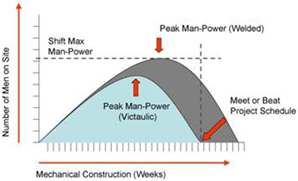

- Requires 45% less man-hours on average over welding

- Eliminate costly fire watch and hazardous fumes and flames

Benefits of the grooved systems:

- Rigidity

- Noise and vibration attenuation

- System maintenance and expansion

- Flexibility

- Seismic stress absorption

- Alignment ease

Victaulic offers a complete line of grooved products for 1/2-24″/15-600mm including couplings, fittings, valves and accessories.

Applications:

Chilled cooling water, condenser water, cooling towers, brine systems, special coolant systems, central chiller, ice chiller systems, air handling units, hot (hydronic) heating, boiler piping systems, dual temperature systems, water source heat pumps, fan coils, coil headers, VAV box with hot water coils.

Advanced Groove System (AGS).

- It starts with a UNIQUE groove:

- Wedge shaped for more strength

- Wider and deeper than the groove in any comparable system

- A Single Groove Profile for all sizes

- Formed using standard Victaulic tools and Patent-pending grooving rolls

- TWO-PIECE HOUSING for all couplings

- Only TWO BOLTS complete assembly

- Visual confirmation of proper joint assembly

- It’s uniquely strong:

- 350 psi/2,410 kPa

- A nominal THREE-TO-ONE safety factor

- TWICE the end-load capabilities

- NO FLAME/NO FUMES

- Accommodates for piping system movement

- A UNION AT EVERY JOINT

Noise & Vibration Attenuation

Mechanical equipment vibrates and vibrations make noise. When those noises become cyclic and droning or arrive in sudden bursts when equipment switches on, then there is a problem. Especially in industrial and/or HVAC applications where buildings are occupied.

Piping System Design

When placed in a formation of three couplings linked near to each other in close proximity to the source of vibration, Victaulic mechanical pipe systems deliver unsurpassed vibration isolation and sound attenuation characteristics

Victaulic flexible couplings provide vibration attenuation in three ways:

- Pipe end separation

- Elastomer gasket

- Ductile iron housing

- Safety

By utilizing Victaulic systems:

- Improve jobsite safety

- Reduce the risk of injuries and associated direct and indirect costs

- Reduce material handling

- Reduce construction man-hours

- Shorten construction schedules

- Reduce total installed costs

- Fewer Men Hours = Less exposure and Project Risk

Victaulic estimates that jobs requiring welding applications demand up to 45% more man-hours on average over Victaulic no-flame piping solutions.

Eliminate the hazards of welding

By utilizing Victaulic mechanical pipe joining systems, contractors can eliminate the hazards of welding on-site. “Welding is among the most dangerous industrial activities. The dangers of welding are fire safety, electric shock, compressed gases, toxic fumes and lack of personal protection for the eyes, hands, feet and body.”

Reduce material handling

30-70% of man-hours and costs are associated with material handling and material handling is directly linked to jobsite injuries. Reduce your material handling through the use of Victaulic

Seismic Testing

Victaulic Couplings Successfully Pass Independent Seismic Testing Program

Victaulic couplings were tested at the ATLSS center, a member of the nationally recognized NEES (Network for Earthquake Engineering Simulations), USA testing group, to prove the reliability of Victaulic grooved system components when exposed to seismic movements. Victaulic couplings ranging in size from 4″-16″ (100 – 400mm) were exposed to accelerations up to 50% greater than the Northridge, California earthquake.

The water-filled assemblies were pressurized to 200psi/1375 kPa for the duration of all tests and no pressure loss or leakage was noted during any of the tests.

Green Building

Victaulic mechanical pipe joining systems provide architects and engineers involved in environmental design with multiple sustainable green building design solutions for piping systems including….

Maintainability of the system

Increased building efficiency

Maintenance, updates and retrofits of grooved mechanical pipe joining systems are as simple as removing and replacing two couplings. Pumps, chillers, strainers and valves can be changed out faster and easier keeping systems running as efficiently as possible.

Better maintenance leads to better building efficiency. The grooved piping system provides a union at every joint for ease and speed of routine system maintanence. Additionally, groove systems allow for system isolation during maintenance which means while one section of the system is down, the rest can remain live.

Elimination of the emission of hazardous weld pollutants

Because of their flameless installation requirements, mechanical pipe joints are inherently safer and easier to work with during system installation and maintenance activities. The flameless fabrication of grooved piping systems make them ideal for HVAC, utility and wastewater applications in highly restricted locations such as trenches, crawl spaces and tunnels, where welding would be particularly hazardous to personnel and property.

Minimizing the potential for contamination under seismic stresses

The integrity of a properly installed grooved piping system minimizes the likelihood of water contamination from leaks, ruptures and other faults resulting from seismic stresses.

Reducing noise pollution

The elastomeric gasket used to seal pipe couplings also creates discontinuity in the piping system. This reduces noise and vibration transmitted through piping from pumps, chillers and other components.